We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

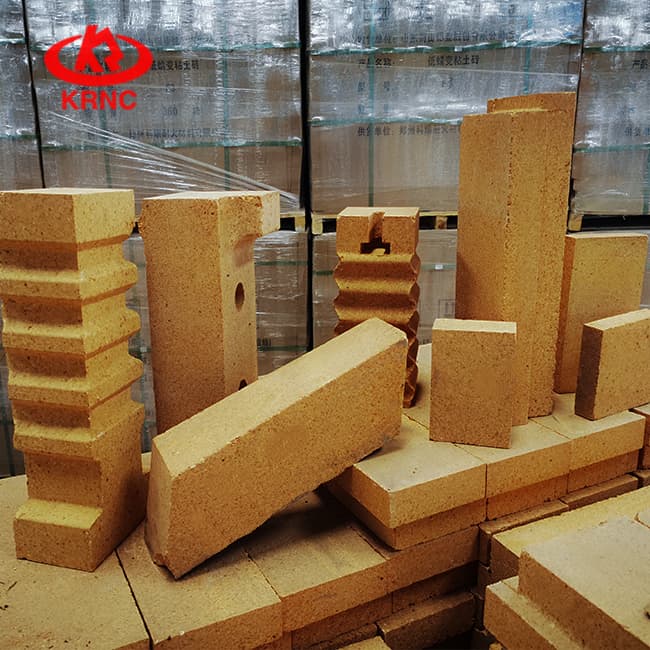

Low porosity fire clay brick introduction

The AlO content of low porosity fire clay brick is generally 30%~40%, and the FeO content is less than 2.0~2.5%. Low porosity fire clay brick is a small man-made block used in construction, easy to process, low price. Low porosity fire clay refractory material is rich in raw materials, with clay as the main raw material, after mud treatment, molding, drying and roasting

Low porosity fire clay brick features

Fire clay brick has good thermal shock resistance, high softening temperature under load, high refractoriness, dense volume density, low porosity and excellent high temperature creep performance.

More relevant refractory products: Anti-corrosion Refractory Mortar

Low porosity fire clay brick index

| Item/Grade | SK-30 | SK-32 | SK-34 | SK-35 |

| Al2O3% (≥) | 30 | 35 | 38 | 45 |

| Fe2O3% (≤) | 2.5 | 2.5 | 2 | 2 |

| Refractoriness(SK) | 30 | 32 | 34 | 35 |

| Refractoriness underload, 0.2MPa, °C (≥) | 1250 | 1300 | 1360 | 1420 |

| Apparent porosity (%) | 22-26 | 20-24 | 20-22 | 18-20 |

| Bulk density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 |

| Cold crushing strength ,MPa (≥) | 40 | 45 | 30 | 40 |

Low porosity fire clay brick application

Fire clay brick are rich in raw materials and are used more widely than any other refractories. It is mainly used in blast furnace, hot blast furnace, cupola, steel drum and pouring steel system and soaking furnace, heating furnace, non-ferrous metal melting furnace, silicate industry and chemical industry kiln and all the chimney and flue of thermal equipment.

Wechat Us

Wechat Us