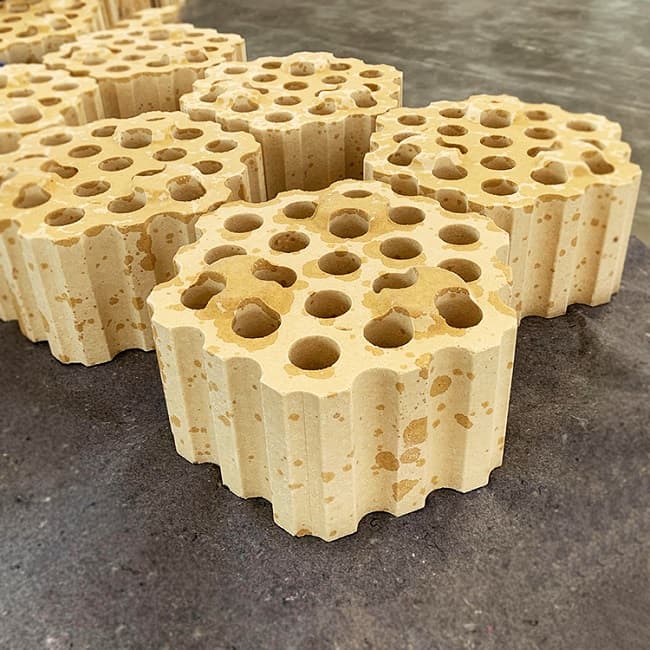

Silica fire brick is an acidic refractory material with good resistance to acid slag erosion. The load softening temperature can reach as high as 1640~1670 ℃, and its volume is relatively stable when used for a long time at high temperatures. The silica fire bricks sold by Kerui Refractory Company are refractory bricks with high fire resistance, good corrosion resistance, slag resistance, and high strength.

What is a silica fire brick

Silica bricks are mainly acidic refractory materials composed of quartz, cristobalite, and a small amount of residual quartz and glass phase. The silica content of silica fire bricks is over 93%, and the starting temperature for load softening is 1620~1670 ℃. Long term use at high temperatures without deformation. Generally, there is no crystal transformation above 600 ℃. Smaller temperature expansion coefficient. High thermal shock resistance. Below 600 ℃, there is a significant transformation of crystal form, significant volume change, and poor thermal shock resistance. Using natural silica as raw material and adding an appropriate amount of mineralizer to promote the conversion of quartz in the green body into phosphorous quartz. Slowly fired at 1350~1430 ℃ in a reducing atmosphere.

Physical property of silica fire bricks

Good acid and slag resistance

Silica bricks belong to acidic refractory materials and have strong resistance to acidic slag erosion, but their resistance to alkaline slag erosion is weak.

High fire resistance

Silica fire bricks have a higher fire resistance than ordinary clay bricks, reaching 1690-1730 ℃.

High load softening temperature

The load softening temperature of silica fire bricks is high, almost close to the fire resistance of silica fire bricks, generally above 1620 ℃, which is the biggest advantage of silica fire bricks.

Low density

The true density of silica bricks is generally 2.33~2.42g/cm3, preferably small. The low true density indicates a complete transformation of quartz crystal form, resulting in a small residual expansion during use.

Poor thermal stability performance

The thermal stability is poor, and the water cooling frequency is only 1-2 times. This is mainly due to the high and low type crystal transformation, so silica fire bricks are not suitable for places with sudden temperature changes.

Poor volume stability performance

Due to poor volume stability and volume expansion during heating, it is necessary to leave appropriate expansion joints when laying bricks.

Notes:

When the kiln working temperature is lower than 600 ~ 700℃, the volume of silica fire brick will have a great change. Because the thermal stability and volume stability of silica bricks are relatively poor, so if the coke oven works at this temperature for a long time, its lining is easy to be damaged.

Physical & chemical index of silica fire brick

| Silica Brick | GZ-95 | GZ-94 | GZ-93 |

| SiO2 | ≥95 | ≥94 | ≥93 |

| Refractoriness, ℃ | 1710 | 1710 | 1690 |

| Apparent Porosity, % | ≤22 | ≤23 | ≤25 |

| Bulk Density, g/cm3 | ≥1.8 | ≥1.8 | ≥1.8 |

| True Density, g/cm3 | ≤2.34 | ≤2.34 | ≤2.34 |

| Cold Crushing Strength, Mpa | ≥35 | ≥35 | ≥35 |

| 0.2Mpa Refractoriness Under Load T0.6, ℃ | ≥1650 | ≥1640 | ≥1620 |

| 20-1000 ℃ Thermal Expansion, % | 1.25 | 1.25 | 1.25 |

| Thermal Conductivity at 1000 ℃ , W/m.K | 1.44 | 1.44 | 1.44 |

Application of silica fire brick

Silica fire brick is the main masonry material of acid smelting equipment, and also the indispensable furnace building material of coke oven and copper melting furnace.

Because of its high softening temperature under load, silica fire brick can also be used on the top of basic open furnace and electric furnace, and even the upper lattice brick of regenerator can also be used for masonry.

Refractory manufacturer of silica brick

Kerui is a professional silica brick firebrick manufacturer, Kerui has a professional construction team and advanced technology, our refractory products have been sold to Russia, South Korea, Ukraine, Brazil, Indonesia, Iran, Thailand and other countries. Kerui has been specializing in refractory performance research, to provide customers with professional services, we hope to become your best partner in China.

Wechat Us

Wechat Us