Chorme corundum brick introduction

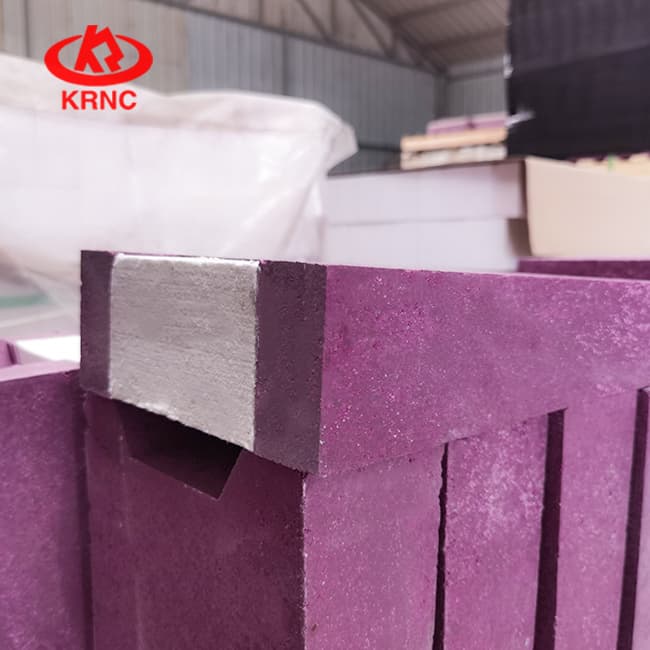

Chrome corundum brick is aluminum oxide powder as the main raw material, adding chrome oxide, etc., through high temperature melting. Its color is red, and its hardness is similar to white corundum, but its toughness is higher than white corundum.

Why are chrome corundum bricks red?

Chrome corundum fire brick is mainly made with corundum components and chrome green. The appearance color of chrome corundum brick is green at the initial stage of forming, but after the reaction with CO through high temperature sintering, the appearance color will turn to red or even purple red. The change of color is determined by the level of chrome content.

Corundum brick is used in industrial kiln under high temperature and high pressure environment, chrome corundum brick and corundum brick both have the same but also have the difference:

1.Fire resistance

Adding Cr2O3 to corundum can not reduce the fire resistance but improve the fire resistance of the material. The refractoriness of chrome corundum brick is greater than 1790℃ and the softening temperature under load is greater than 1700℃.

2.Compressive strength

The normal temperature compressive strength of corundum brick is 70-100MPa, and the normal temperature compressive strength of high-performance chrome corundum brick is generally greater than 150MPa, which is significantly higher than that of corundum brick.

In the firing process of corundum and chrome corundum fire bricks, Al2O3-Cr2O3 solid solution is formed between particles, between particles and fine powder, and between fine powder and fine powder. The solid solution connects particles and fine powder together like a bridge, which greatly improves the strength of materials.

3.Thermal shock stability

When Cr2O3 is added to corundum, the thermal shock stability of the material decreases with the increase of the content of Cr2O3 when the content of Cr2O3 is 10%-66%. In other words, the thermal shock stability of the chrome corundum brick with low content of Cr2O3 is better than that of the chrome corundum brick with high content of Cr2O3.

The thermal shock stability of high performance chrome corundum fire brick is higher than that of corundum brick with the content of Cr2O3 between 12%-20%. In particular, the AKZ chrome corundum brick produced by adding a small amount of phase change additive has better thermal shock stability.

4.Slag erosion resistance

Corundum brick is seriously eroded by slag, slag will penetrate into the brick, and along the internal pores of the brick into the surface, the brick turns brown, almost no residue; There is no obvious chemical reaction between the slag and the surface of the brick. The boundary between the edge of the inner hole and the residue is clear. The slag penetrates little into the brick, and only about 5-10mm thick metamorphic layer is formed around the brick hole. Chrome corundum brick has better chemical corrosion and permeability resistance to gasifier slag than corundum brick, and its structural spalling resistance is better than corundum brick.

Chrome corundum brick price

Chrome corundum fire brick is generally divided into fused cast chrome corundum fire brick and sintered chrome corundum brick, chrome corundum brick production process is different, raw material composition is different, the price is different. So it makes a big difference when you ask different manufacturers to quote you. Corainite recommends that you choose the appropriate chrome corundum brick according to the location of the kiln, which can improve the service life of your kiln, but also reduce your cost.

Application of corundum chorme

Chrome corundum brick is used as lining of glass kiln, drawing glass flow hole cover, plate brick and used in hot metal pretreatment device, waste incinerator, gasifier backing, etc. Corundum brick is used in petrochemical and fertilizer industry of cracking, reformer, metallurgy industry steel furnace, blast furnace and other high temperature kiln lining, kiln tools. Chrome corundum brick is better than corundum brick high temperature resistance and erosion resistance, can meet the different needs of industrial kiln use.

Kerui refractory manufacturers are ready to provide you with free professional refractory consulting services. Kerui Refractory is a reliable refractory manufacturer for customers, and also hopes to become your best partner in China!

Wechat Us

Wechat Us