Compared with high alumina brick, clay fire brick price, corundum brick price is higher than the first two, but corundum brick expensive also has reasons. The reason why corundum brick is expensive is that its raw material composition and high alumina brick, clay brick is not the same.

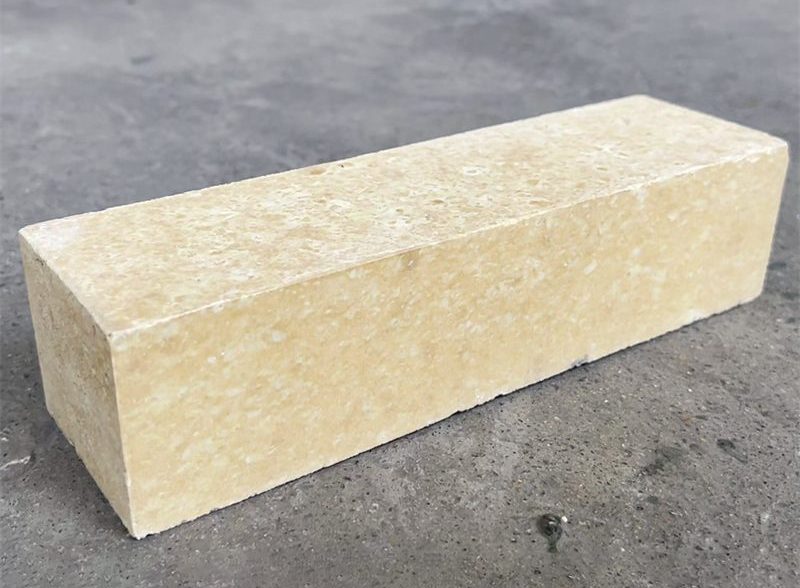

Corundum fire brick refers to refractory brick products with Al2O3 content greater than 90% and refractory products with corundum as the main crystalline phase. High compressive strength at room temperature (up to 340MPa), high softening temperature under load (greater than 1700℃), strong chemical stability, hardness up to 9 Mohs grade, high melting point, acid or alkaline slag, metal and liquid glass have strong resistance.

The basic raw materials of corundum brick are sintered corundum and electric fused corundum, which are respectively made into sintered corundum brick and electric fused corundum brick. Other mineral raw materials can also be added to form composite materials, such as zirconium corundum brick, chrome corundum brick and titanium corundum brick, so as to improve its performance and adapt to various application environments.

Sintered corundum fire brick

Sintered corundum refers to a refractory clinker made of forged alumina (or industrial alumina) as raw material, finely ground into a ball or billet body, and sintered at a high temperature of 1750 ~ 1950℃. Sintered corundum containing Al2O399% or more has a porosity below 4.0% and a volume density of 3.55g·cm³. It has good volume stability and chemical stability at high temperature and is not affected by the erosion of reducing atmosphere, molten glass liquid and metal liquid. It has good mechanical strength and wear resistance at room temperature and high temperature.

Electric fused corundum fire brick

Fused corundum is made of forged alumina or bauxite, which is melted and separated from metals and other impurities by arc furnace in reducing atmosphere, and then condensed. According to the different raw materials and smelting process, common varieties are: fused white corundum, fused brown corundum, dense fused corundum (low porosity corundum), alumina based fused corundum (commonly known as high alumina corundum, sub-white corundum) and zirconium corundum.

In addition, the different prices of corundum bricks in the eyes of customers are just different quotes from refractory manufacturers or suppliers. In the face of these prices, what choice should we make?

First of all, the price of corundum brick is the same as all products. The price is mainly affected by the production cost. The production process of corundum brick from raw material screening, batching, molding, firing, finished products, packaging, delivery. Each of these processes is closely related to the price of high alumina bricks.

The specific impact aspect can refer to the analysis of the next article!

If you have any questions about refractories, please feel free to consult.

Wechat Us

Wechat Us