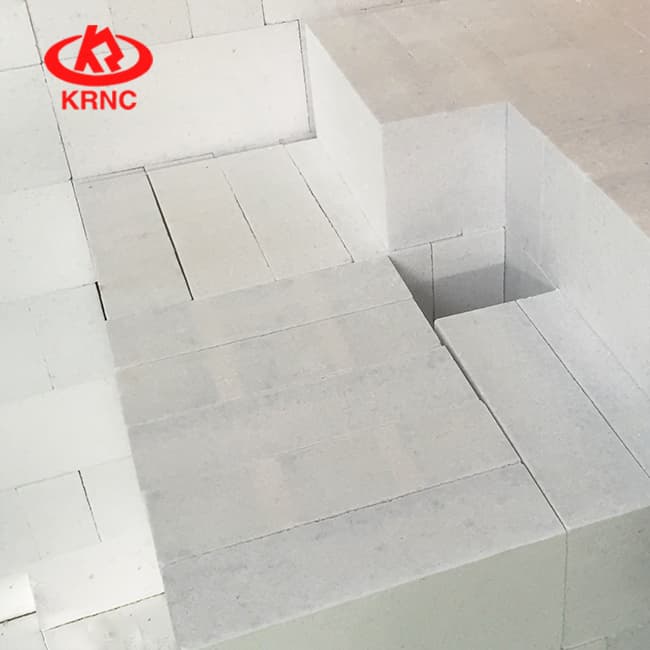

Corundum mullite brick is a high alumina refractory product composed of corundum and mullite main crystalline phase. Kerui corundum mullite brick is made of high-purity or purer raw materials, with white color and accurate size. We also support customized refractory products. Kerui corundum mullite brick has excellent corrosion resistance and wear resistance, strong stability, and is not affected by H2, CO and other reducing gases.

Corundum mullite brick description

Corundum mullite brick is mainly made of fused white corundum sand, aluminum oxide powder and other raw materials. Due to the low melting point of oxide impurities, the high temperature performance of corundum mullite brick will be reduced. In terms of the price of refractory fire bricks, the price of corundum mullite bricks is higher than that of ordinary high alumina bricks.

Corundum mullite brick index

| Item/Index | Mullite Bricks | Resintering Fused Mullite Bricks | Mullite-Corundum Bricks | Corundum-Mullite Bricks |

| Al2O3 | ≥70% | ≥75% | ≥80% | ≥90% |

| SiO2 | ≤25% | ≤23% | ≤18% | ≤8% |

| Fe2O3 | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.3% |

| Apparent Porosity | ≤17% | ≤14% | ≤19% | ≤18% |

| Bulk Density | ≥2.55g/cm | ≥2.65g/cm | ≥2.70g/cm | ≥2.90g/cm |

| Cold Crushing Strength | ≥90MPa | ≥100MPa | ≥80MPa | ≥100MPa |

| Initial Refractoriness Under Load | ≥1630℃ | ≥1700℃ | ≥1650℃ | ≥1700℃ |

Corundum mullite brick price

Corundum mullite brick is generally divided into sintered corundum mullite brick and fused corundum mullite brick. The production process of corundum mullite brick is different, and the price is also different. So when you ask different manufacturers to quote you, there will be great differences. Kerui Refractory recommends that you select appropriate corundum mullite bricks according to the location of the kiln, which can improve the service life of your kiln and reduce your cost.

Corundum mullite brick production process

Corundum mullite brick can be used as aggregate with mullite particles, α- Al2O3 powder is used as powder, or fused or sintered corundum particles as aggregate, and synthetic mullite powder as powder. The aggregate and powder shall be proportioned according to a certain proportion and particle size, and the sulfite pulp waste liquid shall be used as the binding agent. The materials shall be added in a certain order, fully mixed and even, and then formed by friction brick press or hydraulic brick press. After the brick is dried, it is fired at 1650-1750 ℃.

The manufacturing process of fused or sintered corundum particles as aggregate for corundum mullite brick will produce poor density. Therefore, it is not widely used.

Notes:

The pure mullite raw material synthesized with industrial aluminum oxide powder and pure clay, bauxite or silica as raw materials, especially the alkali metal oxide content should be as low as possible. The products made with mullite particles as aggregate have good thermal shock resistance, but slightly poor corrosion resistance. The products made with corundum sand as aggregate have good corrosion resistance, but slightly poor thermal shock resistance.

Corundum mullite brick application

Corundum mullite brick is mainly used in petrochemical industry, high-temperature hot-blast furnace, glass furnace and ceramic firing kiln furniture.

Manufacturer of corundum mullite brick

The purpose of Kerui Refractory is to serve the global high-temperature industry. If you currently have a high-temperature equipment construction project and need high-quality corundum mullite bricks for masonry, Kerui Refractory Factory is ready to provide you with free professional refractory consulting services. Kerui Refractory is a reliable refractory manufacturer for customers, and also hopes to become your best partner in China.

Wechat Us

Wechat Us